In today's environment of ever more powerful and compact electronics, successful thermal administration is not a luxurious – it's a necessity. Overheating may lead to lessened general performance, system instability, and in some cases catastrophic failure. which is the place tailor made heat sinks are available in. Unlike off-the-shelf solutions, tailor made patterns are tailored to the specific requirements of the software, making sure optimal warmth dissipation and responsible Procedure. This guideline will explore the crucial part of tailor made heat sinks, specially Extruded Profiles Heatsink, in many industries and supply insights into building and balancing Value with functionality.

Table of contents:

Key Industries That reap the benefits of customized warmth Sink methods

tips on how to layout a Custom Heat Sink for ideal Thermal Management

Price tag vs. overall performance: Balancing Custom warmth Sink technical specs

critical Industries That gain from custom made Heat Sink alternatives

many industries depend on custom warmth sinks to take care of the effectiveness and longevity in their electronic components. The telecommunications sector, Extruded Profiles Heatsink with its dense networking equipment, Advantages tremendously from tailored thermal remedies that stop overheating and ensure uninterrupted service. equally, the power electronics industry, working with substantial-voltage and substantial-latest applications, needs strong warmth sinks to handle the intensive warmth generated by energy transistors and rectifiers. In addition, the aerospace and defense industries, where by reliability underneath Excessive conditions is paramount, depend upon tailor made designs to resist severe environments and manage significant method features. Even in clinical tools, the place precision and basic safety are critical, custom warmth sinks play an important part in blocking overheating and ensuring accurate diagnoses and remedies.

how you can style a tailor made warmth Sink for exceptional Thermal administration

developing a successful custom made warmth sink entails very careful consideration of numerous factors. 1st, being familiar with the heat source and its thermal properties is very important. This involves pinpointing the power dissipation, temperature boundaries, and mounting prerequisites. subsequent, deciding upon the ideal content is critical. Aluminum is a popular selection as a consequence of its excellent thermal conductivity, lightweight, and price-effectiveness, creating Extruded Profiles Heatsink a common Remedy. Copper provides exceptional thermal efficiency but is heavier and costlier. The geometry of the warmth sink is additionally essential. Fin density, fin peak, and base thickness all impression the warmth sink's capability to dissipate heat. Computational Fluid Dynamics (CFD) simulations can be used to enhance the design and predict thermal overall performance ahead of Bodily prototypes are designed. contemplating airflow and ventilation in the enclosure can also be critical, as good airflow improves the warmth sink's efficiency.

Price vs. effectiveness: Balancing Custom Heat Sink Specifications

when maximizing thermal general performance is really a primary objective, cost is also an important thought when planning custom warmth sinks. greater-performance elements like copper will improve the Over-all Value in comparison with aluminum. Similarly, elaborate geometries that demand intricate machining or specialised manufacturing processes will also generate up bills. picking out the appropriate production method, like extrusion for Extruded Profiles Heatsink, can significantly influence Price tag-performance. it is important to thoroughly Consider the thermal needs of your software and discover parts in which overall performance can be balanced with cost price savings. one example is, optimizing fin density or choosing a more Price-powerful alloy can normally offer a excellent stability among thermal effectiveness and price range. Sourcing your custom made warmth sinks from reputable producers who provide style and design assistance and worth engineering can additional assist in attaining the optimal Price-effectiveness ratio. Renxin Precision, for example, offers A selection of customized warmth sink answers and can offer professional steering on optimizing your design for both equally performance and value.

In summary, custom heat sinks are necessary components for making certain the reliability and efficiency of electronic units in an array of industries. By knowing The crucial element design issues and carefully balancing Expense with general performance, you'll be able to produce a customized thermal Alternative that fulfills the particular desires of your application. Really don't hesitate to examine the main advantages of Extruded Profiles Heatsink and consult with with expert manufacturers like Renxin Precision to uncover the proper Answer for the thermal administration difficulties. start out optimizing your thermal performance now!

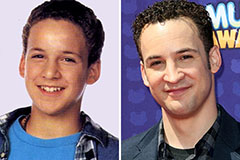

Ben Savage Then & Now!

Ben Savage Then & Now! Mason Gamble Then & Now!

Mason Gamble Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!